Metal decay has shaped civilizations, economies, and technological advancement throughout human history, yet its underlying mechanisms remain a mystery to many.

From the rust that forms on a forgotten bicycle to the patina gracing ancient bronze statues, corrosion represents one of nature’s most persistent chemical processes. Understanding this phenomenon isn’t merely an academic exercise—it’s a crucial endeavor that affects infrastructure safety, economic stability, and the preservation of our cultural heritage. The annual global cost of corrosion exceeds $2.5 trillion, representing approximately 3.4% of the world’s GDP, making it one of the most expensive natural processes affecting modern society.

This fascinating intersection of chemistry, physics, and materials science reveals how metals interact with their environment in ways both destructive and beautiful. Whether you’re a curious homeowner wondering about that rust spot on your car or a professional seeking deeper insights into material preservation, understanding corrosion opens doors to better maintenance strategies, innovative protection methods, and appreciation for the chemical ballet occurring all around us.

🔬 The Chemistry Behind Metal Decay: Understanding Oxidation at Its Core

At its fundamental level, corrosion represents an electrochemical process where metals return to their more stable, natural state. Most metals exist in nature as ores—compounds combined with oxygen, sulfur, or other elements. The refining process requires significant energy to extract pure metal, creating an unstable state that nature constantly works to reverse.

The oxidation process involves the transfer of electrons from metal atoms to surrounding molecules, typically oxygen and water. When iron corrodes, for instance, iron atoms lose electrons and become positively charged ions. These electrons then combine with oxygen and water to form hydroxide ions, which react with the iron ions to create iron oxide—the reddish-brown substance we call rust.

This electrochemical reaction requires three essential components: an anode (where oxidation occurs), a cathode (where reduction happens), and an electrolyte (a conductive medium, often water with dissolved salts). Remove any of these elements, and corrosion cannot proceed. This principle forms the foundation of most corrosion prevention strategies employed across industries worldwide.

The Different Faces of Corrosion: Types and Manifestations

Corrosion doesn’t present itself uniformly across all situations. Different environmental conditions and metal compositions create distinct corrosion patterns, each with unique characteristics and challenges:

- Uniform corrosion: The most predictable form, occurring evenly across exposed surfaces, commonly seen as rust on steel structures

- Pitting corrosion: Localized attack creating small holes or cavities, particularly dangerous because it can penetrate deeply while showing minimal surface damage

- Crevice corrosion: Occurs in confined spaces where stagnant solutions accumulate, such as under gaskets or at joints

- Galvanic corrosion: Results when two dissimilar metals contact each other in the presence of an electrolyte, accelerating decay in the more reactive metal

- Stress corrosion cracking: A combination of tensile stress and corrosive environment causing sudden catastrophic failure

- Intergranular corrosion: Attack along grain boundaries in metal alloys, often invisible from the surface until significant damage occurs

⚙️ Environmental Factors: The Catalysts of Decay

The rate and severity of metal corrosion depend heavily on environmental conditions. Understanding these factors enables better prediction of material lifespan and informs protection strategies tailored to specific conditions.

Moisture stands as the most critical factor in corrosion progression. Water serves as the electrolyte necessary for electrochemical reactions, and its presence dramatically accelerates metal decay. Relative humidity above 60% typically triggers corrosion in susceptible metals, while condensation creates particularly aggressive conditions by concentrating dissolved salts and contaminants.

Oxygen availability directly influences corrosion rates, as it participates in the cathodic reaction. Interestingly, corrosion doesn’t always increase linearly with oxygen concentration—some environments with limited oxygen can produce different corrosion types or even slow certain processes. Submerged metals in stagnant water, for example, may corrode more slowly than those in well-oxygenated flowing water.

Temperature and Its Complex Relationship with Corrosion

Temperature affects corrosion through multiple pathways. Higher temperatures generally accelerate chemical reactions, approximately doubling reaction rates for every 10°C increase. However, temperature also influences oxygen solubility in water (decreasing with heat), moisture condensation patterns, and the protective properties of corrosion product layers.

In marine environments, the splash zone—where seawater intermittently wets surfaces—often experiences the most aggressive corrosion. This region combines high oxygen availability, salt concentration through evaporation, and repeated wetting-drying cycles that prevent stable protective film formation.

🛡️ Noble Metals and Natural Resistance: Nature’s Corrosion Warriors

Not all metals succumb equally to corrosion. The nobility of a metal—its tendency to resist oxidation—varies dramatically across the periodic table. Gold, platinum, and other precious metals maintain their luster for millennia precisely because of their remarkable corrosion resistance, explaining their historical value and continued use in applications demanding longevity.

The galvanic series ranks metals according to their electrochemical potential in specific electrolytes. When dissimilar metals contact each other, the more active (anodic) metal corrodes preferentially while the nobler (cathodic) metal remains protected. This principle underlies both corrosion problems and protection strategies used across industries.

| Metal | Relative Nobility | Common Applications |

|---|---|---|

| Platinum | Most Noble | Jewelry, catalysts, electronics |

| Gold | Very Noble | Jewelry, electronics, dentistry |

| Titanium | Noble (passive) | Aerospace, medical implants |

| Stainless Steel | Moderately Noble | Kitchen equipment, construction |

| Carbon Steel | Active | Structural applications, machinery |

| Aluminum | Active (passive) | Aircraft, packaging, construction |

| Zinc | Very Active | Galvanizing, batteries, alloys |

| Magnesium | Most Active | Lightweight alloys, sacrificial anodes |

The Passivation Phenomenon: When Corrosion Protects Itself

Some metals develop protective oxide layers that dramatically slow further corrosion, a process called passivation. Aluminum, chromium, and titanium exemplify this behavior, forming thin, adherent oxide films that act as barriers between the metal and its environment. These passive films, often only nanometers thick, provide remarkable protection that allows these reactive metals to function in corrosive environments.

Stainless steel’s corrosion resistance stems entirely from passivation. Chromium additions (typically 10.5% or higher) create a chromium oxide layer that regenerates if damaged, explaining why stainless steel maintains its appearance and structural integrity across diverse applications. However, passive films can break down under certain conditions—chloride ions in marine environments, for example, can penetrate and destabilize these protective layers, leading to aggressive localized corrosion.

🔧 Modern Protection Strategies: Fighting Back Against Decay

Humanity has developed sophisticated approaches to combat corrosion, employing physical barriers, chemical treatments, electrochemical methods, and material selection strategies. The optimal approach depends on the specific application, environmental conditions, economic considerations, and required service life.

Protective coatings represent the most common corrosion prevention method, creating physical barriers between metal and environment. Paints, powder coatings, galvanizing (zinc coating), and electroplating with noble metals each offer distinct advantages. Modern coating systems often employ multiple layers—primers for adhesion and corrosion inhibition, intermediate layers for build and barrier properties, and topcoats for environmental resistance and appearance.

Cathodic Protection: Turning Electrochemistry Against Itself

Cathodic protection exploits the electrochemical nature of corrosion by making the protected metal a cathode in an electrochemical cell. Two approaches achieve this: sacrificial anode systems and impressed current systems.

Sacrificial anodes use more active metals (typically zinc, aluminum, or magnesium) connected to the structure being protected. These anodes corrode preferentially, protecting the attached structure. This elegant solution requires no external power, making it ideal for ships, underground pipes, and offshore platforms. However, anodes require periodic replacement as they’re consumed.

Impressed current systems use an external power source to force protective current flow, offering advantages for larger structures and longer service life without component replacement. These systems protect pipelines spanning thousands of kilometers, large ships, and critical infrastructure where corrosion failure would have catastrophic consequences.

💡 Corrosion Monitoring and Detection: Staying Ahead of Decay

Preventing corrosion failure requires not just protection but also vigilant monitoring. Modern technology offers increasingly sophisticated methods for detecting corrosion before it compromises structural integrity, enabling predictive maintenance that prevents failures while optimizing inspection costs.

Visual inspection remains the foundation of corrosion monitoring, but advanced techniques now supplement human observation. Ultrasonic thickness gauging measures remaining wall thickness in pipes and vessels, detecting material loss from corrosion. Radiographic testing reveals internal corrosion invisible from outside. Acoustic emission monitoring detects sounds produced by crack growth and active corrosion processes.

Emerging technologies leverage artificial intelligence and Internet of Things (IoT) sensors for continuous corrosion monitoring. Smart sensors embedded in structures measure corrosion rates in real-time, transmitting data for analysis. Machine learning algorithms identify patterns predicting where and when corrosion problems will emerge, enabling targeted interventions before failures occur.

The Economics of Corrosion Management

Effective corrosion management balances protection costs against failure consequences. While prevention always costs less than repair, determining optimal protection levels requires considering factors including initial costs, maintenance requirements, expected service life, and failure ramifications.

Industries approach this calculation differently based on their specific risks. Aerospace applications justify expensive corrosion-resistant materials and rigorous protection because failure costs lives and involves enormous financial losses. Chemical processing facilities invest heavily in corrosion control because failures can cause environmental disasters and production shutdowns. Meanwhile, temporary structures may receive minimal protection since their brief service life doesn’t justify extensive corrosion investment.

🏛️ Historical Preservation: Learning from Ancient Corrosion

Archaeological artifacts provide fascinating insights into long-term corrosion behavior while presenting unique preservation challenges. The Damascus Gate in Delhi houses an iron pillar standing for over 1,600 years without significant rusting—a metallurgical mystery attributed to its unusual phosphorus content, climate conditions, and absence of industrial pollutants creating a protective passive layer.

Bronze statues develop patina—greenish surface layers of copper carbonate and sulfate—that actually protects underlying metal while creating aesthetically valued coloration. Conservation specialists must balance preservation with maintaining historical appearance, sometimes deliberately promoting protective patina formation while preventing destructive corrosion.

Shipwrecks present particularly complex corrosion scenarios. The Titanic, resting on the North Atlantic seabed since 1912, deteriorates through electrochemical corrosion accelerated by iron-eating bacteria. Researchers estimate the wreck may collapse completely within decades, making documentation urgent while studying unique deep-sea corrosion mechanisms.

🌍 Environmental Considerations: Green Approaches to Corrosion Control

Traditional corrosion protection methods sometimes employ environmentally harmful substances—chromate coatings, for example, offer excellent protection but pose health and environmental risks. Modern approaches increasingly emphasize sustainable corrosion management that protects both metals and ecosystems.

Green corrosion inhibitors derived from plant extracts show promise as environmentally benign alternatives to traditional toxic compounds. Tannins, alkaloids, and other natural compounds can adsorb onto metal surfaces, forming protective barriers comparable to synthetic inhibitors. Research continues into optimizing these bio-based solutions for industrial applications.

The circular economy concept influences corrosion management through emphasis on material longevity and recyclability. Designing for corrosion resistance extends product lifespans, reducing resource consumption and waste generation. When components eventually corrode beyond service, recycling recovers valuable materials, closing resource loops and minimizing environmental impact.

🚀 Future Horizons: Innovations Reshaping Corrosion Science

Nanotechnology opens exciting possibilities for corrosion protection through nanostructured coatings offering superior barrier properties, self-healing capabilities, and multifunctional performance. Nanoparticles incorporated into coatings can provide active corrosion inhibition, antimicrobial properties, and enhanced mechanical strength simultaneously.

Self-healing materials represent a paradigm shift in corrosion protection. These smart materials contain microcapsules or vascular networks filled with healing agents that release when coating damage occurs, automatically repairing breaches before corrosion initiates. While still largely experimental, early applications show promise for extending coating lifetimes dramatically.

Computational modeling and simulation increasingly complement experimental corrosion research. Sophisticated software predicts corrosion behavior under various conditions, optimizes protection strategies, and screens new materials virtually before expensive physical testing. These digital tools accelerate development cycles while reducing research costs.

⚡ Bringing It All Together: The Continuing Dance Between Metal and Environment

The story of metal corrosion encompasses chemistry, physics, engineering, economics, and art. This natural process that has challenged humanity throughout history continues driving innovation in materials science, protection technologies, and monitoring systems. Understanding corrosion mechanisms empowers better decision-making about material selection, protection strategies, and maintenance practices across countless applications.

From the molecular interactions at metal surfaces to the global economic impact of infrastructure decay, corrosion science touches nearly every aspect of modern life. The rust on a garden tool and the engineered corrosion resistance of space station components both arise from the same fundamental electrochemical principles, demonstrating how basic science scales from everyday experiences to extraordinary achievements.

As we face challenges of aging infrastructure, resource scarcity, and environmental sustainability, expertise in corrosion management becomes increasingly critical. The metals forming our built environment will continue their inexorable return toward thermodynamic stability, but human ingenuity continually develops more effective strategies to slow this process, preserving the structures and systems our civilization depends upon.

Whether you’re protecting your personal property from rust, specifying materials for professional applications, or simply curious about the chemical processes shaping the world around you, understanding corrosion provides valuable insights into the dynamic relationship between materials and their environment—a relationship that will continue defining technological progress for generations to come. 🔬

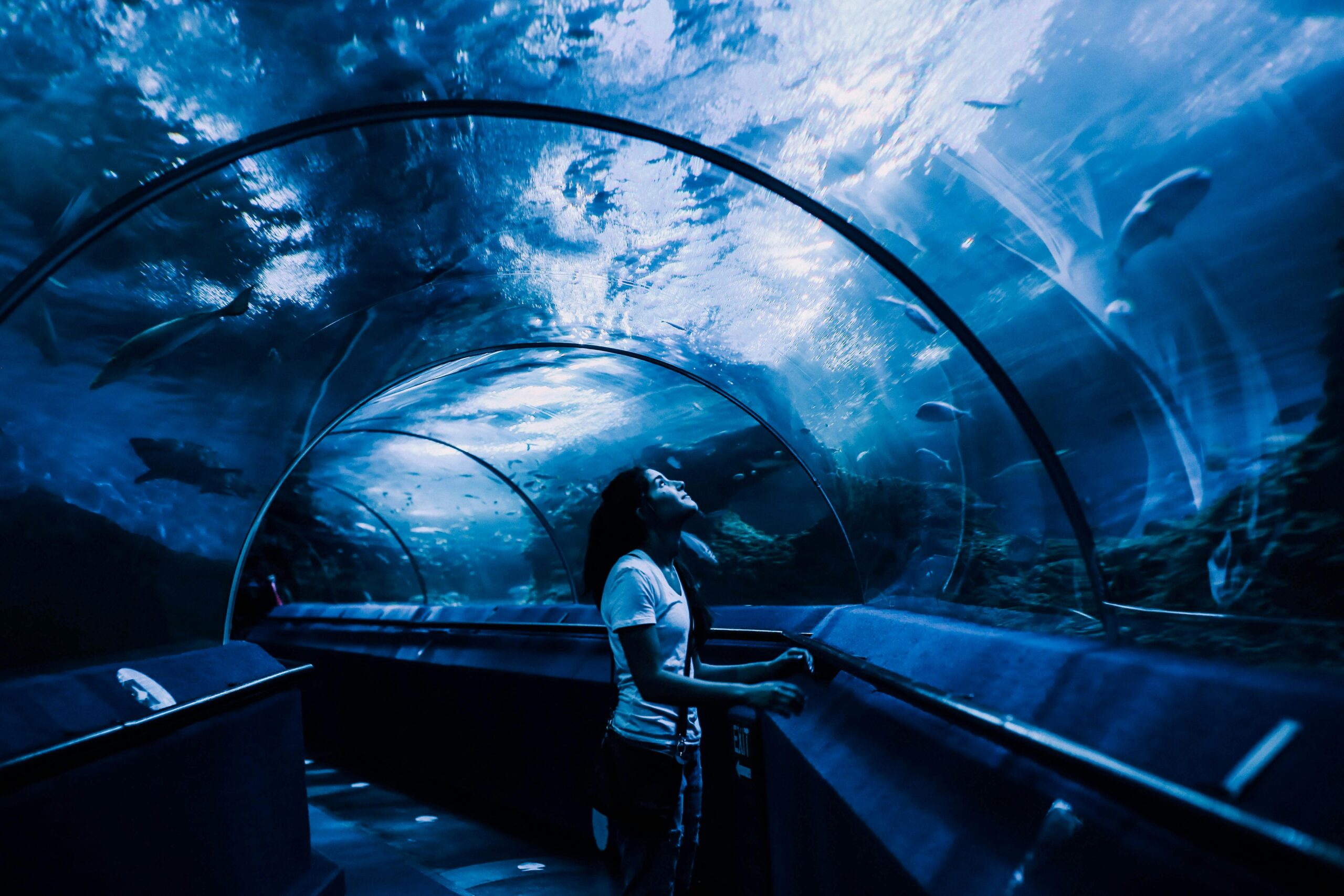

Toni Santos is a visual storyteller and archival artist whose work dives deep into the submerged narratives of underwater archaeology. Through a lens tuned to forgotten depths, Toni explores the silent poetry of lost worlds beneath the waves — where history sleeps in salt and sediment.

Guided by a fascination with sunken relics, ancient ports, and shipwrecked civilizations, Toni’s creative journey flows through coral-covered amphorae, eroded coins, and barnacle-encrusted artifacts. Each piece he creates or curates is a visual meditation on the passage of time — a dialogue between what is buried and what still speaks.

Blending design, storytelling, and historical interpretation, Toni brings to the surface the aesthetics of maritime memory. His work captures the textures of decay and preservation, revealing beauty in rust, ruin, and ruin’s resilience. Through his artistry, he reanimates the traces of vanished cultures that now rest on ocean floors, lost to maps but not to meaning.

As the voice behind Vizovex, Toni shares curated visuals, thoughtful essays, and reconstructed impressions of archaeological findings beneath the sea. He invites others to see underwater ruins not as remnants, but as thresholds to wonder — where history is softened by water, yet sharpened by myth.

His work is a tribute to:

The mystery of civilizations claimed by the sea

The haunting elegance of artifacts lost to time

The silent dialogue between water, memory, and stone

Whether you’re drawn to ancient maritime empires, forgotten coastal rituals, or the melancholic beauty of sunken ships, Toni welcomes you to descend into a space where the past is submerged but never silenced — one relic, one current, one discovery at a time.